03 June 2020

LACROIX Electronics

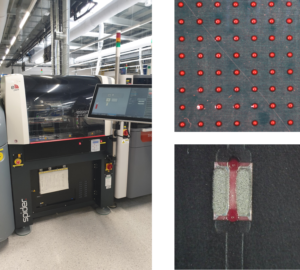

As the industrial sector seeks to develop smaller and smaller products, electronic miniaturisation is a key challenge for companies such as the Electronics activity of LACROIX. In-line fitting technologies for surface-mounted components are at the cutting edge, but fitting precision can be difficult to maintain when it comes to components barely visible to the naked eye. This is where our partner Essemtec comes in, with its Spider platform for applying droplets of glue to hold miniature components in place.

A successful experiment at our factory in Poland

Using the innovative technology known as jetting, the robot performs a rapid and ultra-precise mechanical action, which projects drops of glue via a syringe. The application of these very small drops of glue supports the components as they pass through the reflow oven in order to retain their fitting precision. This therefore enables the Electronics activity of LACROIX to ensure consistent control over the manipulation of fluid materials and to enhance precision for the fitting of miniature components. The company thus achieves the performance required for microelectronics.

Strong potential for aeronautics and industrial IoT markets

Tried and tested for the needs of our automotive customers, we also wish to offer this technological advance to our industrial customers and to the IIOT sector, where there is a demand for robust miniaturisation

Furthermore, the value created by industrial IoT items comes directly from the sensors, so it is important that these are perfectly fitted in order to record the required data in optimal fashion.

Connected high-precision solutions, a technology for the future

Following a training course given by Essemtec, the Electronics activity of LACROIX can now easily create programs to connect the machine to the entire digital chain system. Interconnecting production systems in this way enables the establishment of a continuous link between data related to design, manufacture, inspection and testing.

So this is only the beginning for this technology, which has a bright future at LACROIX!

Testimony

-

Benjamin :

Benjamin :“Validated by our Polish factory, the aim is to develop this technology throughout the company’s other production plants, firstly in Tunisia, then within the future electronics factory, “Symbiose”, which is set to open in 2021 in France,”

Benjamin Gauchenot, VP Operations & Quality at the Electronics activity of LACROIX.

Wróblewski :

Wróblewski :“This is an extremely efficient high-precision machine. After the first uses, we can now easily double our drops of glue per hour capacity and meet the quality requirements of our customers.”

Andrzej Wróblewski, Process Engineering Manager at the Electronics activity of LACROIX, Poland,

Genonceau :

Genonceau :“The glue application solution provided by Essemtec and its partner SEICA has successfully met the technological challenges set by the Electronics activity of LACROIX. The teams worked together on Essemtec’s Spider platform. They adopted a collaborative approach, oriented at all times towards the resolution of technical issues. We demonstrated our abilities to address the challenges faced by LACROIX, a key player in Europe, and we want to thank LACROIX for recognising the effectiveness of our technical solution.”

Franck Genonceau, French Market Commercial Affairs Officer at Essemtec’s.

Plus d'articles

3 tips for reshoring through automation

Expert's take

Securing the Supply Chain: The Ideal Way to Make Your Products Last the Distance

Driving industrial projects in the electronics sector through "coopetition"

Expert's take

Design for Test: how to ensure the quality of my electronic product by optimizing its production cost?

Expert's take