19 July 2023

LACROIX Electronics

As digitalization enhances quality and customer satisfaction, LACROIX has decided to test a digital solution for managing instruction sheets across all workstations. This system provides personalized job guidance and instructions enabling our manufacturing operators to excel in their mission. Let’s dive into the topic.

Reliable Instructions for Standardized Production

It is crucial to have up-to-date, clear, and personalized work instructions.

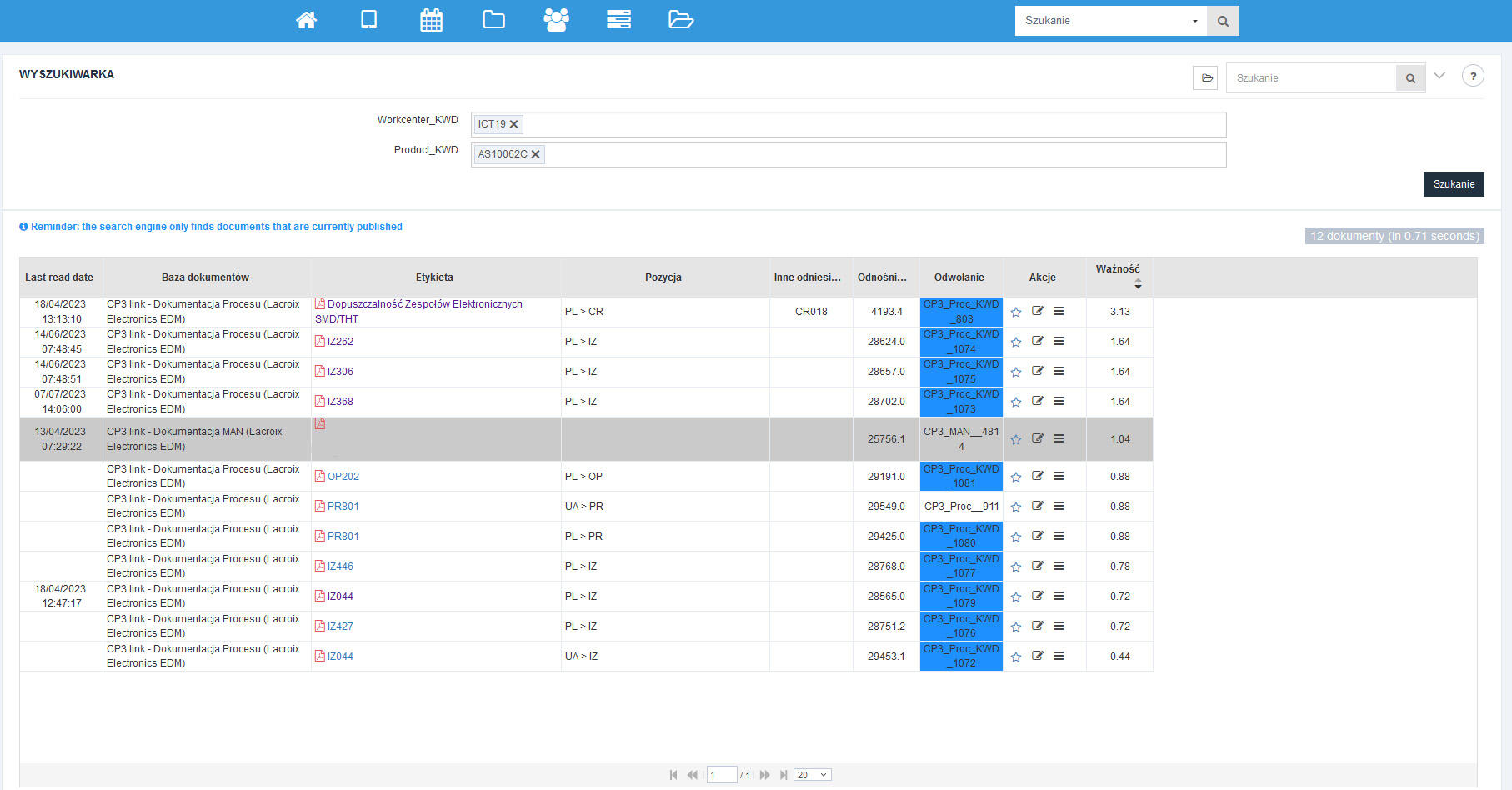

LACROIX’s digital work instruction release solution changes how operators receive and interact with these guidelines. Instead of relying on stacks of paper, they now enter all the necessary data into the digital system, streamlining the entire process.

The 3 Benefits of Digital Transformation of Work Instructions Release (WIR):

- Simplified Change Management

The digital work instruction release application simplifies change management by providing a centralized platform for new instructions. Whether they originate internally or are requested by clients, the system ensures the versioning of work instructions. Immediately available at workstations, the risk of errors is minimized. - Improved Tracking and Communication

One of the noteworthy features of the solution is the enhanced tracking and communication capabilities. When a specific work instruction is updated, the system notifies the operators in real-time. LACROIX utilizes a color-coded system that identifies which operator has read the new instruction. The date and time of the modification acknowledgment are recorded. - Paper Elimination

By transitioning from paper-based instructions to digital formats, LACROIX significantly reduces its paper and ink consumption. This effort aligns with its commitment to sustainable development.

Successful Pilot Project!

💻 Tested…

The digital transformation of the process began at LACROIX’s Polish factory with an experimental group of 18 workstations for an automotive sector client. Over three weeks, this pilot project collected feedback from the operators.

Based on this feedback, the continuous and engineering teams have worked with developers to fix critical points and optimize the solution. After three weeks of operation and testing, the solution was validated by all main users (production, quality, engineering).

And approved! ✅

This solution enhances the implementation of changes and the distribution of work instructions, resulting in improved quality. Whether the change stems from internal process enhancements or modifications requested by the client, the system has demonstrated its effectiveness in process improvement.

In the coming months, the solution will be implemented across several hundred workstations in both buildings of LACROIX’s Polish factory. A more comprehensive deployment plan is being considered to amplify the benefits of digitization across all factories.

To conclude, LACROIX’s transition from paper-based work instructions, to a digital distribution solution marks a significant milestone in its pursuit of operational excellence and reliability. By leveraging digital technologies, LACROIX empowers its operators and paves the way for future advancements in the digitization of the electronics sector.