The importance of a comprehensive Testing Strategy for electronic boards

Testing is a crucial step in the development cycle of an electronic board. A well-defined strategy enables identifying anomalies from the earliest project phases, thus avoiding high correction costs during production and ensuring the quality of delivered products.

Our approach integrates:

Defining exhaustive test plans

in-circuit tests, functional tests, boundary scan, memory tests

Test

automation

to ensure optimal coverage and result repeatability

Implementation of test environments

for continuous validation at each development stage

Measuring specific KPIs

to track progress and optimize test performance

Validation and non-regression: Ensuring quality throughout the lifecycle

At LACROIX, we implement rigorous validation processes to ensure the proper functioning of electronic boards throughout their lifecycle. Our non-regression tests verify that no new revision compromises existing functionalities.

Our key steps:

- Systematic execution of non-regression tests with each design modification

- Analysis of technical debt to identify and limit vulnerability points

- Performance validation under real-world conditions

- Implementation of continuous improvement for validation protocols

DfT: Designing for Testability from the Start

Design for Test (DfT) is an engineering methodology that integrates testability from the earliest phases of electronic board design. This approach optimizes testing processes, reduces costs, and accelerates time-to-market.

Our experts implement DfT best practices:

- Integration of JTAG and boundary scan test architectures to improve test coverage

- Design of specific test points to facilitate in-circuit testing (ICT)

- Implementation of built-in self-test (BIST) functions for field validation

- Optimization of critical component and interface testability

- Consideration of test constraints from the electronic schematic design phase

Our comprehensive approach to electronic board validation

LACROIX offers a global methodology that combines hardware and software testing for complete validation of your electronic boards:

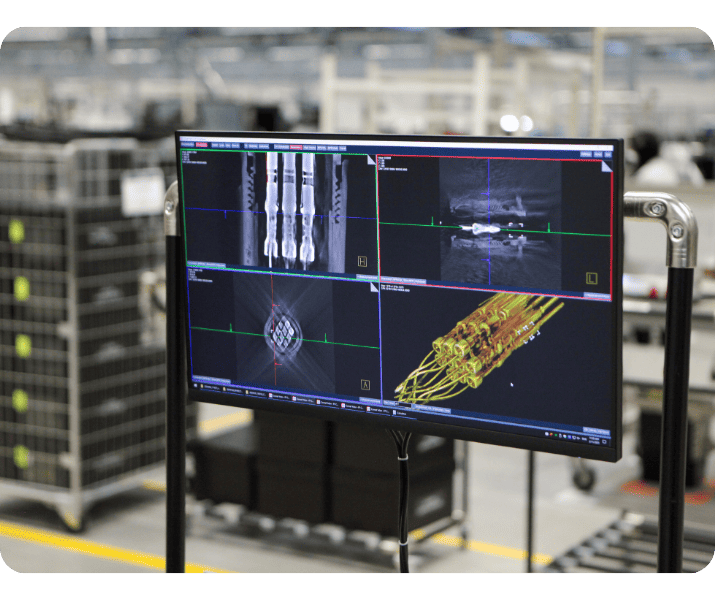

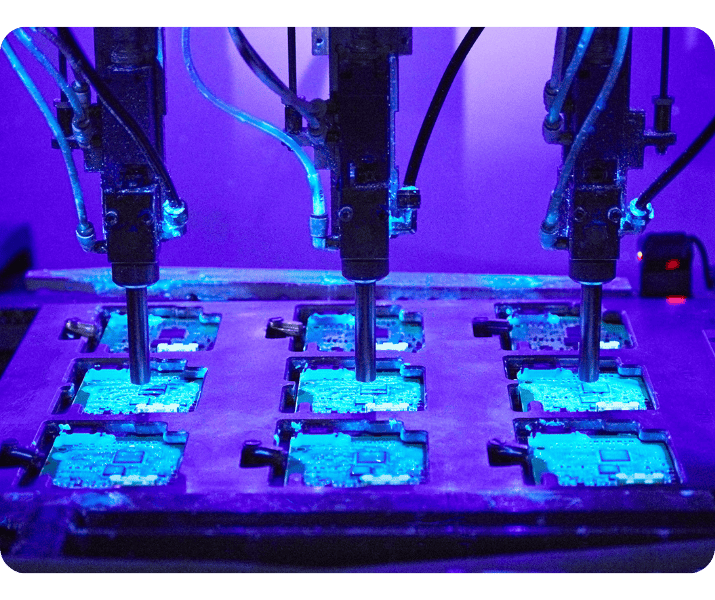

- Structural tests (AOI, AXI, ICT) to validate the physical integrity of boards

- Customized functional tests to verify board behavior under real conditions

- System validation integrating hardware and software dimensions

- Accelerated reliability tests (HALT/HASS) to evaluate product durability

- Failure analysis and debugging tests to anticipate potential issues

Why choose LACROIX for your electronic board testing and validation?

With recognized expertise in electronic design and production, LACROIX offers solutions adapted to the requirements of the most critical industries, from automotive to aeronautics, healthcare, and connected industry.

Our strengths:

- A design center (Impulse) with DfT experts for optimized design

- State-of-the-art test equipment (flying probe testers, ICT, AOI, AXI)

- Expertise in Industry 4.0 for industrialized and optimized testing

- A customized approach to meet the specific constraints of each project

- International presence to support multi-region deployments

Accelerate the Time-to-Market of your project

Optimizing the reliability and quality of your electronic boards requires an advanced testing strategy and a structured DfT approach. With LACROIX, benefit from expert support to ensure the success of your electronic projects.