An integrated approach for a seamless transition between prototyping and production

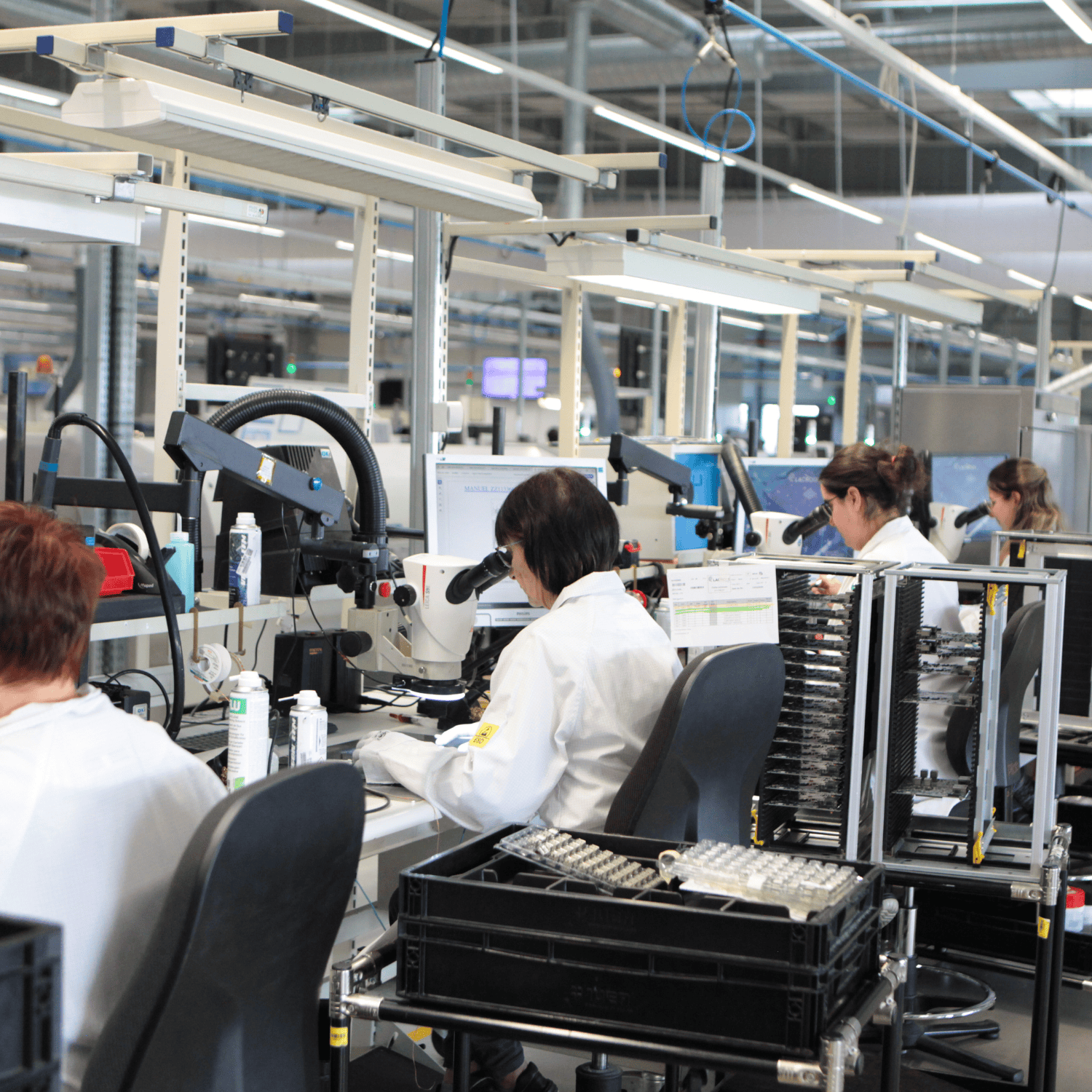

Since 2005, our rapid prototyping units, located directly within our production sites, have enabled us to quickly meet the functional validation needs of electronic boards before their transition to mass production. By integrating design, manufacturability, and testing, we help reduce time-to-market and optimize product reliability.

With simplified processes and a dedicated organization, we ensure responsiveness and technical expertise. 100% of serial (and pre-series) products go through a prototyping phase, a critical step before design freeze. Moreover, our rapid prototyping lines, equipped like serial production lines, guarantee a smooth transition to industrial manufacturing.

A state-of-the-art industrial environment for high-performance prototypes

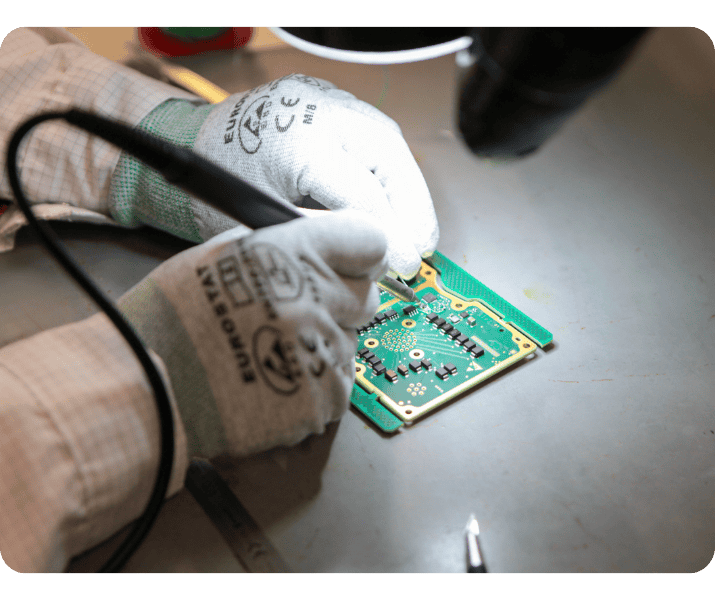

Our prototyping units are equipped with high-value industrial tools:

- Screen printing and SMT placement machines: Providing optimal precision for component assembly,

- Reflow oven and vapor phase (ASSCOM QUICKY800): Ensuring assembly quality for the most demanding components,

- Mobile probe tester TAKAYA APT9400: Rigorous control of printed circuit boards,

- Soldering and repair equipment: Maximum flexibility for quick adjustments.

This infrastructure enables the production of functional prototypes in record time while maintaining optimal quality.

An offer tailored to every business segments

Since 2005

over 75K prototypes delivered

More than 150 clients

With over 75,000 prototypes delivered and collaboration with more than 150 clients across diverse sectors—industrial, automotive, avionics and medical—we have gained significant experience in executing complex projects. This expertise allows us to meet the most demanding requirements, whether it involves tight deadlines or ensuring maximum reliability.

LACROIX: a partner for your innovations

More than just a supplier, our prototyping units are designed to be true catalysts for your projects. By integrating the latest technologies and working closely with your teams, we promote product/process optimization and minimize risks associated with transitioning to production.

Why choose an integrated approach?

- Technical expertise: Close collaboration with your technical teams to ensure tailored solutions,

- Flexibility and responsiveness:An agile organization to address IoT project challenges,

- Industrial quality: Prototypes ready for serial production without compromise,

- Continuous innovation: Integration of the latest technologies to support your ambitions.

Ready to bring your ideas to life?

Whether you are in the design phase or ready to move to industrialization, our teams are here to support you. Contact us to explore solutions that will bring your IoT innovations to life.