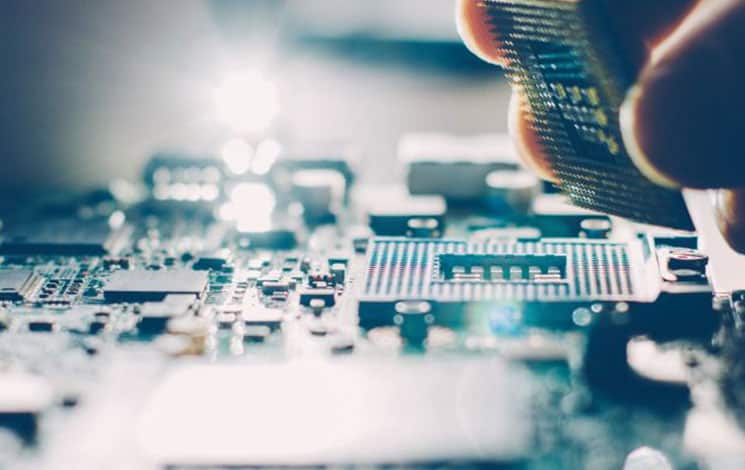

For an industrial company like us, automation is characterized by all the techniques and processes that make it possible to automate repetitive actions with low added value on our production lines.

Sergiusz Sonnenfeld

Test Engineering & Automation Manager

Electronics activity of LACROIX

Automation for our customers, factories and employees

As you can see, the primary goal of automation is to improve our industrial performance, while freeing up time for our operators so that they can focus on more interesting and complex tasks. So, drudgery is reduced or even eliminated in some manual operations.

Obviously, the concept of competitiveness comes into play in this equation. The more competitive our production equipment is, the more attractive we will be to our customers. Increasing productivity and our ability to produce in large volumes is therefore key.

With digitalization, automation is one of the key pillars of our strategy, which we have been deploying in our production plants for several years.

Automation brings numerous benefits to customers

- A significant competitive edge: Automation effectively makes it possible to optimize production costs and thus envisage the relocation of large series in Europe and the bringing together of our factories with those of our customers (known as “nearshoring”).

- Enhanced production quality: Automation reduces the risk of errors that could be made by employees, particularly in operations requiring high precision. Here, reliability is key.

- Extended flexibility: In some cases, automation offers greater flexibility with regard to production rates and volumes. Production and delivery times are therefore shortened, providing customers with a better cost/quality/lead time ratio.

The creation of a unit dedicated to automation

To meet the growing demands of our customers in terms of volume, precision and cost, we have set up a unit dedicated to automation. A new position has been created to coordinate these activities, the Group Automation Manager (my current job).

For over a year now, a cross-functional team distributed across the four countries where our production plants Nouvelle fenêtre are located (France, Germany, Poland and Tunisia) has been experimenting with new processes day after day.

Organisation in this way enables us to increase our expertise in automation by creating an expert network comprising 10 people who are in constant contact with each other to discuss ongoing projects. Standardizing our automation processes is also an important aspect of our approach. Our customers, whether from the industrial, automotive, home automation or avionics sectors, must have access to the same production standards. Of course, we take the specificities of each plant into account.

Robots, cobots… Where are we with them?

Let’s look at robots first

These are automated movement devices that enable objects to be manipulated. Operating in a closed environment, robots, whether fixed or mobile, are programmable and automatically controlled. Able to multitask, they offer numerous industrial applications and optimize cycle times and job productivity.

Then, there are the cobots

These are collaborative robots that can be adapted to perform several handling activities in a single day. Equipped with safety sensors, they can work safely with operators. There is a difference between cohabitation and collaboration:

- In cohabitation, the cobot operates in “co-proximity” with the operator. Each performs their task without direct interaction.

- In collaboration, there is actual interaction between cobot and operator. For example, the cobot passes the product to the operator (or vice versa).

In addition to the robots and cobots present in our factories, we can also find AGVs for automated equipment transport and automated logistics systems (the automated store Exotec, for example).

On our side, we work with reputable suppliers such as Fanuc, Mitsubishi, MIR and Omron to deploy automation projects with the support of organisations such as We Network Nouvelle fenêtre. Our robots and cobots respond to different use cases: handling, placement, soldering, screwing, assembly, integration, transport, etc.

Automation in key figures…

Family portrait of automated equipment

Weeboo: Cobot for loading and unloading reels on an X-ray counting machine

- 500 reels per day

- Free loading by the operator

- Internal/multi-customer use

Fanuc: Robot for loading and unloading testers, stripping press and packaging

- Cycle time: 20 seconds

- Industrial market

Timon : AGV (Automated Guided Vehicule), automatic extraction of finished products

- 300 jobs per week

- 50 km travelled per week

- Multi-market

Omron : Automatic screwing

- 20,000 screws per week

- Working in co-proximity with operators

- Industrial market

Exotec : Automated warehouse fitted with the Skypod system

- Structure measuring ~500 m2

- 6,720 containers stored on 21 levels

- 7 robots

- Multi-customer

Automated production line: Loading and unloading testers

- Cycle time 8 seconds

- 25 product references

- Home automation market

Intégration : Automatic integration station

- 5 processes in one unit

- 48 products per hour

- Automotive market

FCT tester: Handling of automated functional testers

- 2 testers and 1 screwing station

- 3 stations embedded in a system

- 150 products per hour

- Automotive market

Soldering robot

- 5 seconds per soldering point

- 4 product references

- Home automation market

A few words about the author: Sergiusz Sonnenfeld

Passionate about new technologies, Sergiusz has worked for more than 20 years in LACROIX’s Electronics Activity at the Polish production plant located in Kwidzyn. He has held many positions, starting as a repair technician in the technical department. Today, he is both the Test Engineering & Automation Manager and Group Automation Manager

A project? Contact us!

Looking for a partner? Then contact us!

Today, we systematically offer our customers projects that include automation. We’re only at the beginning of automation, and our ambition is strong…