Why redesign?

Redesign is a response to the many challenges faced by manufacturers:

- Component obsolescence : Elements of your product are no longer available? We identify compatible alternatives or rethink the PCB architecture

- Cost optimisation : A modernised design can improve performance and reduce production and assembly costs

- ompliance with new standards : Does your product need to adapt to regulatory and environmental developments? We adjust it to current requirements.

- Reducing your carbon footprint : We apply eco-design principles to minimise the environmental impact and promote better product recyclability

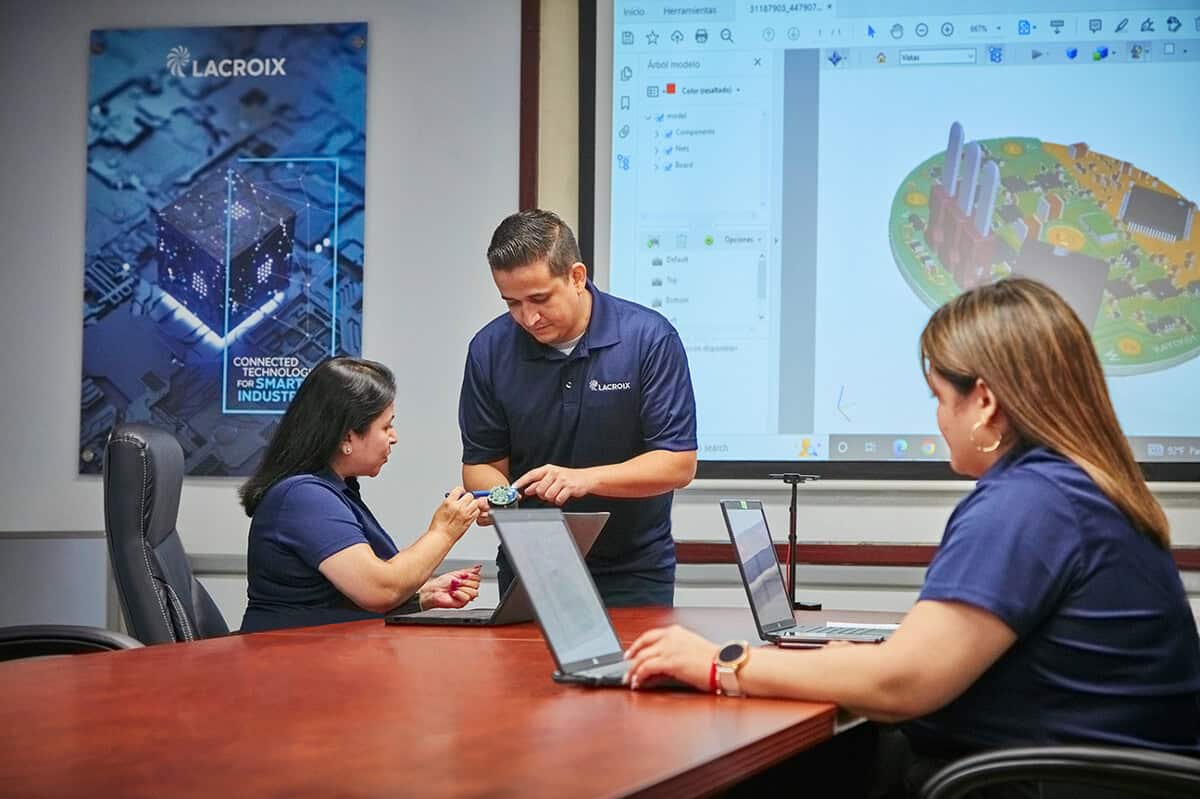

Our approach to electronic redesign

At LACROIX, electronic redesign is more than just an update. We carry out in-depth work to ensure smooth integration into your production chain, taking into account three fundamental pillars:

1- Analysis &

technical audit

Study of the bill of materials (BOM), PCB routing and industrial and environmental constraints

2- Optimization proposals

Adaptation of components, new architectures and integration of eco-design principles for a more sustainable product

3- Tests &

validation

Rapid prototyping, functional tests and industrial trials to guarantee reliable, high-performance redesign

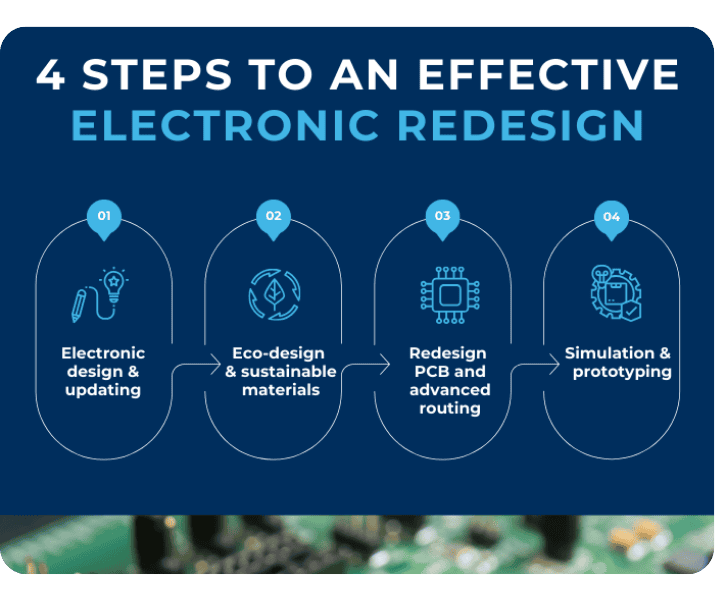

Our key services for

an effective redesign

1- Electronic design and updating : Optimisation of schematics and choice of components to improve reliability, energy consumption and reparability

2- PCB redesign and advanced routing : Modification of PCB layouts and layers to take account of production and recyclability requirements

3- Simulation & prototyping : Pre-production testing to ensure compliance, minimise waste and optimise the use of resources

4- Eco-design and sustainable materials : Selection of components with low environmental impact and improved modularity to extend product life

A redesign with industrialization and environmental impact in mind

By directly integrating the principles of Design for eXcellence (DfX) and eco-design, we maximize production efficiency while reducing its environmental footprint:

- DfM (Design for Manufacturing) : Simplifying manufacturing to reduce scrap and improve reliability

- DfP (Design for Procurement) : Optimized selection of components to guarantee availability and limit the risk of obsolescence

- DfT (Design for Testability) : addition of elements to facilitate quality control testing and future maintenance

- DfS (Design for Sustainability) : Integration of recyclable materials and reduction of component energy consumption

Act now for high-performance redesign

Would you like to modernize your electronic products, secure your production and adopt a more sustainable approach? Our experts are with you every step of the way.