Our expertise and strategic approach to process design

Successful industrialization relies on a rigorous methodology, combining industry best practices and cutting-edge technologies. At LACROIX, we deploy a structured, high-performance process to ensure a smooth, sustainable ramp-up. This is based on 4 essential levers:

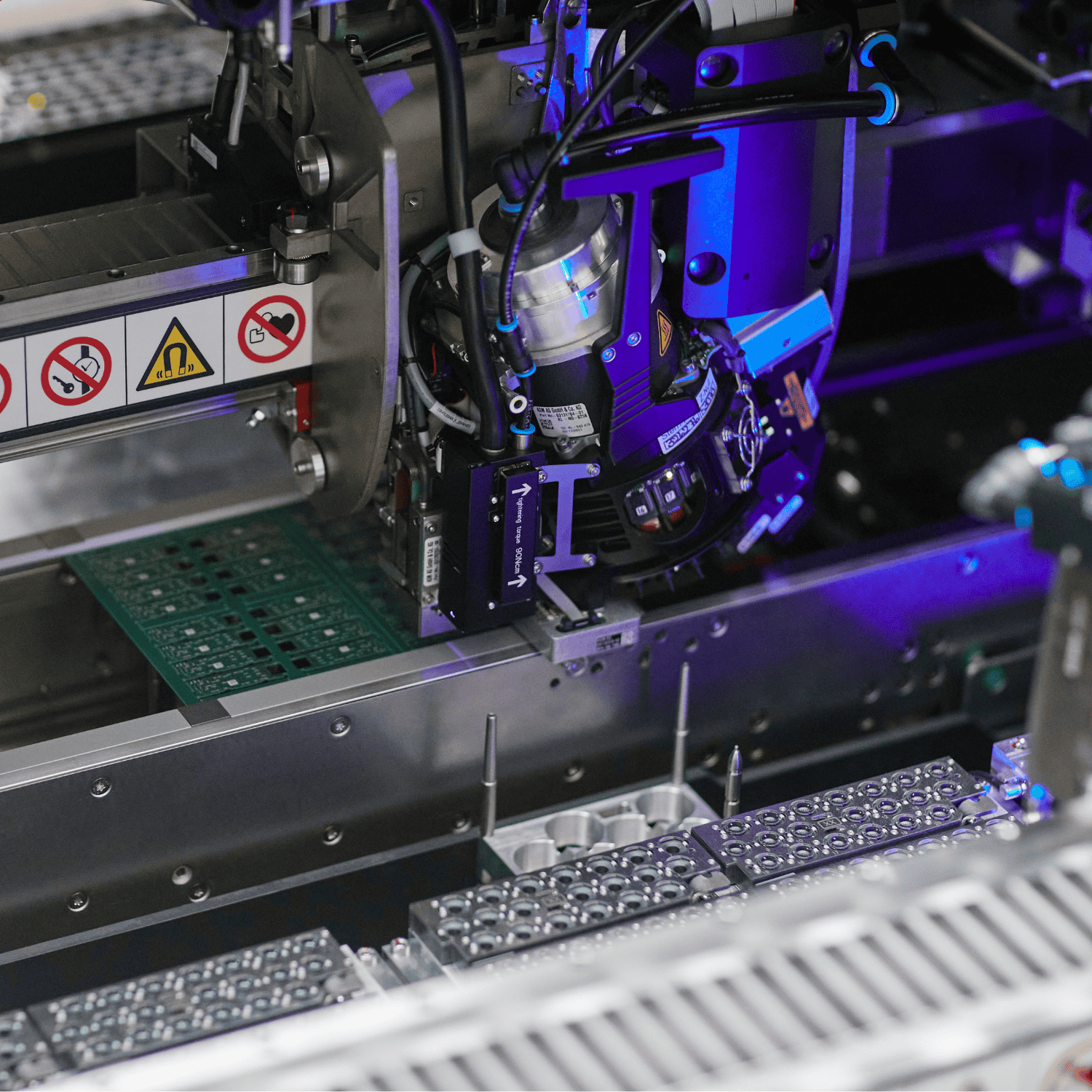

Selection of appropriate technological equipment

We conduct an in-depth analysis of product requirements to integrate the most efficient machines and production processes, ensuring quality and profitability

Definition & validation of assembly processes

Each manufacturing step is meticulously studied to ensure optimum reproducibility and repeatability, thanks to advanced optical, in-circuit and functional test benches

Optimization

of production flow

By applying lean manufacturing principles and leveraging real-time data, we maximize production line efficiency while minimizing costs

Compliance and quality requirements

Our processes are designed to meet the most stringent industrial standards (ISO, IPC, etc.), ensuring product reliability and safety

1- Electing the right equipment and technologies

One of the pillars of process design is selecting the most suitable machines and technologies for the project’s needs. This choice is based on several criteria:

- The complexity of the product and components to be assembled

- The expected production volumes

- Precision and reliability requirements

- Automation and flexibility of production lines

At LACROIX, we integrate the latest production innovations to ensure an agile and high-performance process

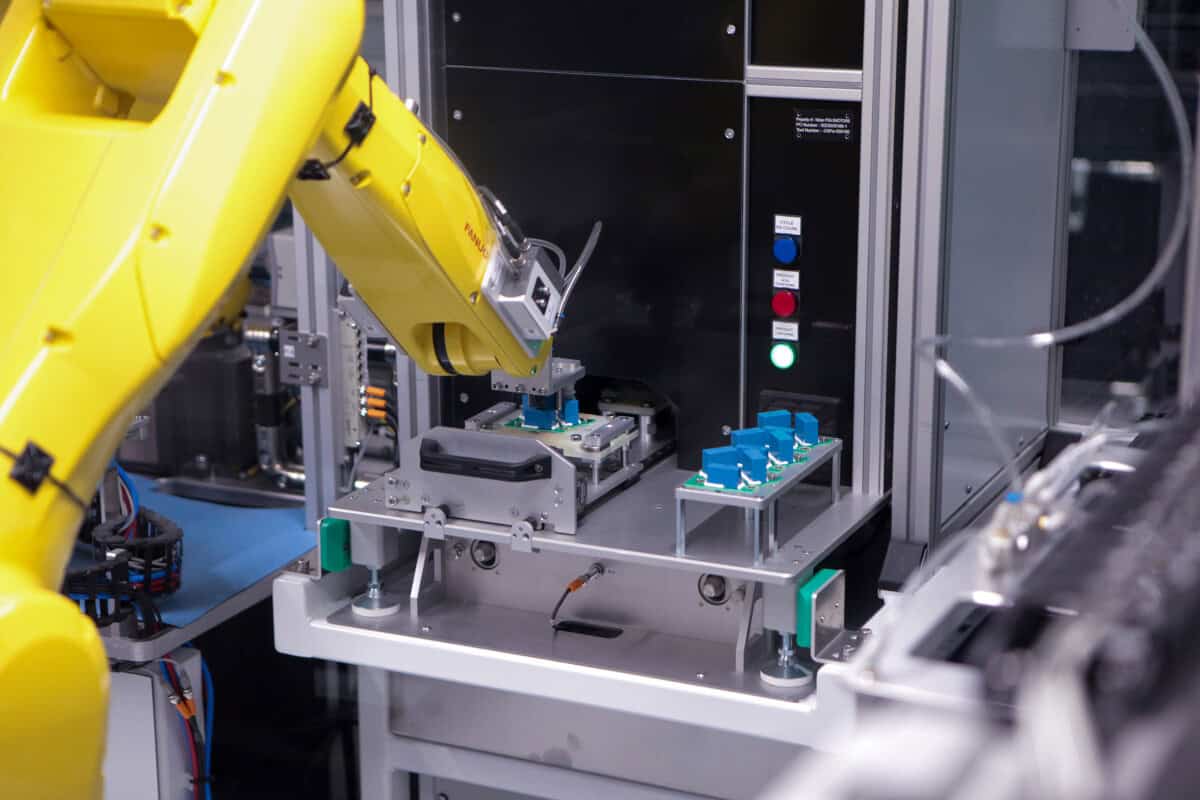

2- Integration of testing and process validation

Testing and validating the process before production launch is a crucial step in anticipating problems and ensuring optimal quality. This includes:

- Feasibility and material compatibility tests

- Implementation of automated test benches

- Performance analyses under real conditions

- Validations in compliance with industry standards (ISO, IPC, etc.)

LACROIX deploys advanced testing and validation solutions, ensuring a robust and reliable process.

3- Optimization and continuous improvement

Process design does not stop at production launch. To maintain long-term competitiveness, it is essential to continuously optimize industrial performance:

- Improving yields and quality

- Reducing waste and production costs

- Integrating IoT and real-time monitoring tools

- Technological watch to adopt the latest innovations

LACROIX applies lean manufacturing and industry 4.0 principles for smarter and more sustainable production.

Optimize your industrialization with LACROIX

Accelerate your projects by leveraging our process design expertise. From conception to production, we support you to ensure an efficient and competitive market launch.