Testimony of Émilie Morice, Process Engineer for the Electronics activity at LACROIX

What does the electronic coating stage bring?

E : Varnishing is the principal means of robustifying boards, and serves to protect them in their operating environment, so that they can withstand given conditions of humidity or high temperatures, for example. This operation, which takes place at the end of the manufacturing process, is known as tropicalization. A very thin layer of varnish, 30 to 70 microns thick, is applied. This extends board life and ensures reliable operation in environments unsuitable for electronics.

What are the different types of PCB coating?

E: There are 4 ways to varnish a card :

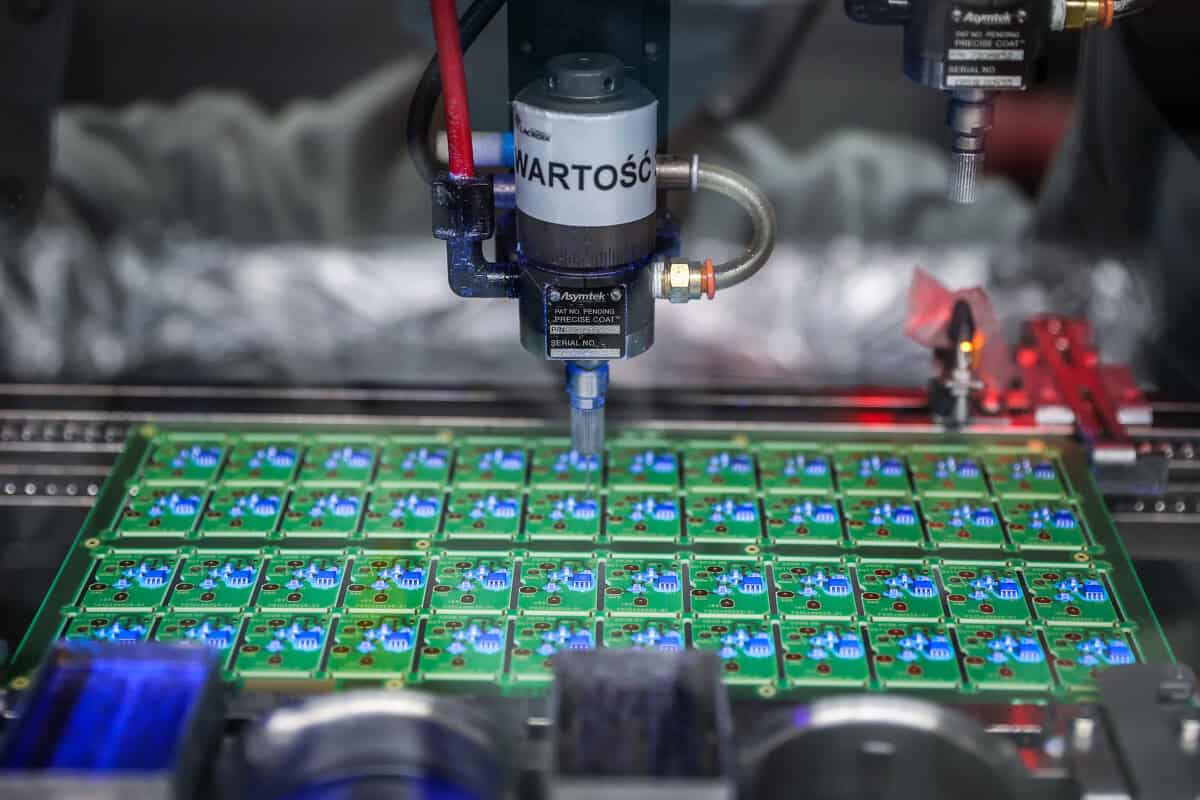

- automatic (or selective) varnishing

- spray varnishing

- dip varnishing

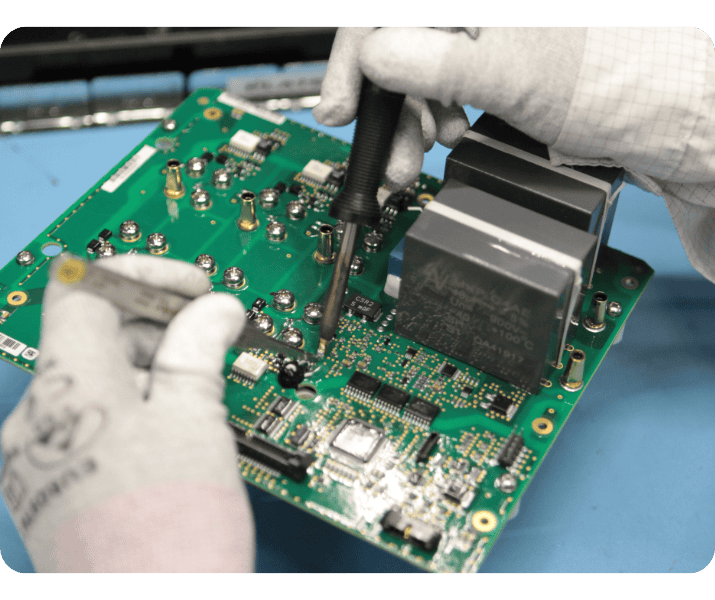

- brush varnishing

We choose the method best suited to the card design and annual production volumes. Selective varnishing is not only automatic and therefore more repeatable, but also eliminates the need for masking. Spray or dip coating, on the other hand, requires masking, but has the advantage of reaching areas that are inaccessible to the robot.

There are also 4 different types of chemistry:

- acrylic, which offers fairly basic protection

- silicone, for high temperatures and humidity

- polyurethane, more resistant to chemicals

- epoxy, rarer

LACROIX’s Electronics activity carries out all techniques and chemistries in its French plant.

Which varnish is best suited to the aerospace industry?

E : It all depends on where the card is going to be, but often the choice is acrylic. There’s a decision tree for selecting the chemistry best suited to the need. It’s not a good idea to apply a polyurethane varnish that’s difficult to repair, if an acrylic varnish is perfectly suited to the protection required.

Is varnishing a major step in the card-making process?

E : This is a very important step, and one that needs to be considered right from the product design stage. The process involves constraints that must be anticipated, even if it means revising certain aspects of the card design. Poorly-prepared varnishing requires more handling, and can therefore drive up costs! Neglecting the importance of this stage can lead to retouching, quality problems or a reduction in the area covered by the varnish. At LACROIX, we’re fortunate to have a particularly well-informed and sensitive design office, as we regularly discuss constraints in the field.

How is the Beaupréau plant equipped?

E : We are equipped with automatic dispensing machines. There’s also a part of the workshop dedicated to masking and two manual dispensing booths. We also have a 3D printer that enables us to produce our own masking caps.