Working smarter via Lean principles

PCBA and HLA assembly lines/work cells design incorporates these basic principles:

- Where possible, design for excellence (DFX) guidelines are followed to minimize defect opportunities and variation, while improving throughput

- Assembly lines/work cells must be designed in a way that minimizes travel time and floor space utilization

- Handling is minimized through automation wherever possible

- PCBA lines have all processes including tests arranged inline for faster throughput and process integrity

- When automation is proposed, the solution must meet throughput goals and pay for itself within one year.

An efficient solution for eliminating bottlenecks

Takt time is a key metric in setting up production lines. The German word “takt” translates to pulse or beat.

Methods engineers pay close attention to balancing equipment in highly automated areas, such as the surface-mount component placement zone (SMT), as well as the takt time of secondary and final assembly operations.

The goal: a smooth workflow with minimal work-in-progress or handling throughout the manufacturing cycle.

PCBA Examples

Semi-automated Assembly for Specialized Lighting

In the case of a specialized lighting product where each unit was over 50 inches in length, specialized equipment was required from paste deposition through final assembly. Additionally, because each PCBA had hundreds of LED placements, the production process required closed-loop real-time feedback to monitor yield throughout the process.

Optimization of the SMT part: A Careful Choice

For the SMT portion of the project, the engineering team in the Juarez, Mexico facility did an evaluation of three brands of placement machines’ capabilities and total footprint. The next step was to determine speed and integration compatibility with existing equipment. With placement accuracy being nearly equal among the machines and all three supporting the industry standard schema communication protocol, it came down to size and speed.

The selection was based on the size and speed of the equipment. The placement accuracy was similar among the three machines. Additionally, they all used the standard LACROIX communication protocol. One machine outperformed the other two by approximately 12% in terms of placement speed. Despite having a slightly larger footprint, its speed provided a clear advantage.

Innovation in Testing Processes

This drove a need to innovate in a complementary test process which utilized camera sensing to perform a “global” test where the entire board was measured with a single pass to ensure takt time stayed in balance with the SMT line.

Improved quality and efficiency with the right system

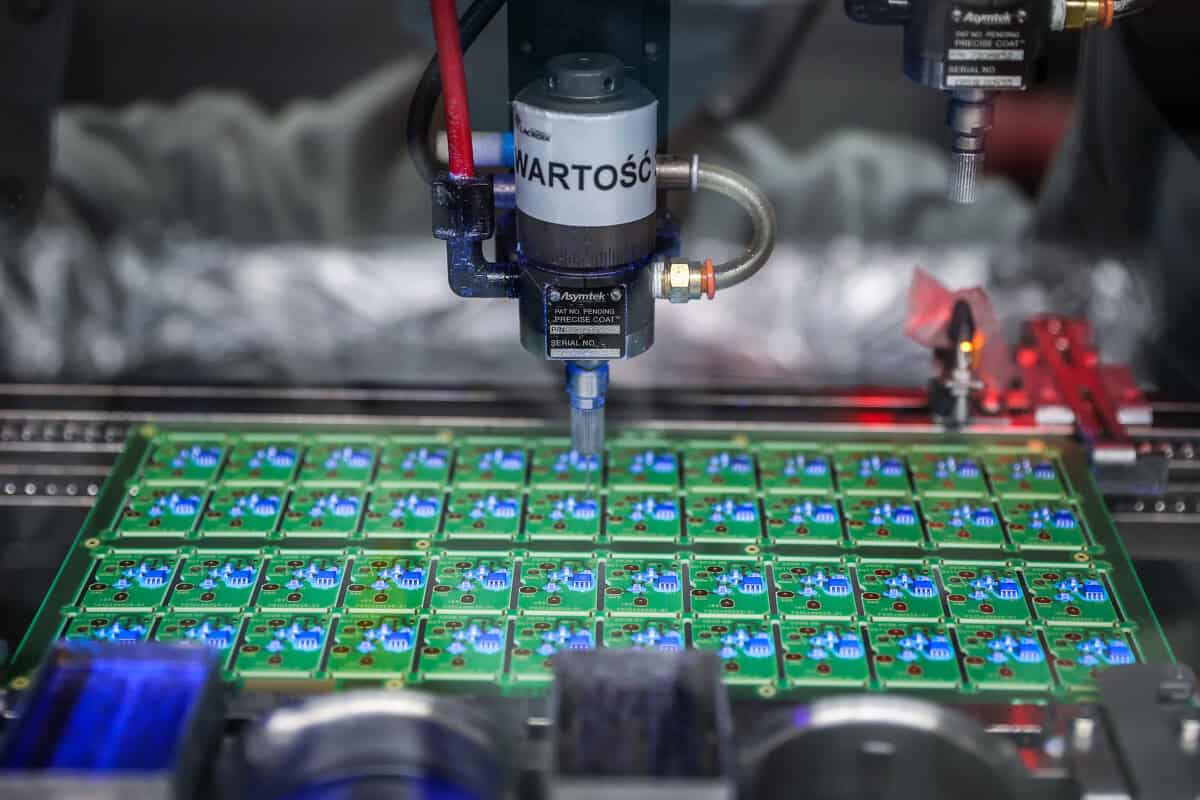

For conformal coating, the team worked with an existing equipment supplier to modify the platform they’d standardized on with special spray nozzles that achieved the coverage required and still maintained takt time metrics. The efficiencies achieved with the modified design drove a need to add a third SMT placement machine for line balance, and the throughput improvements kept this equipment addition cost neutral.

Advanced process for a balanced production line

A semi-automated final assembly process was developed that utilizes a robotic screw machine, robotic end cap placement, and automated inspection along with operators for manual assembly operations.

The result of this process was a balanced production line with minimal handling or transport of very delicate assemblies. Inline inspection and test provide real-time feedback on yield, enabling rapid correction of any issues related to component quality or process workmanship.

Customer benefits: Improved Quality and Responsivenes

When project volumes permit, automation improves quality and efficiency in assembly, testing, and complex operations.

« The team noticed that their automation efforts resulted in four times the production while reducing production staff by three-quarters and floor space requirements by 50 percent. »

Continuous flow production and scalable automation allow LACROIX to increase its production capacities. The efficiencies of automating large projects free up manpower and space for new projects.

Employees are redirected to new projects with less automation. This ensures skilled workforce availability and employees have more variety in their tasks. Cross-training further improves employee versatility.

Looking to boost your factory’s performance through data?

At LACROIX, we digitize industrial monitoring to enable faster, more effective decision-making.