Why these levers are now essential for electronics manufacturers?

Product life cycles are getting shorter. With fast-changing technologies, growing design complexity, and mounting cost pressure, every week saved matters.

Traditional sequential models where design and industrialization are separated, no longer meet the market’s agility needs.

Success now depends on integrating industrial constraints directly into the design phase.

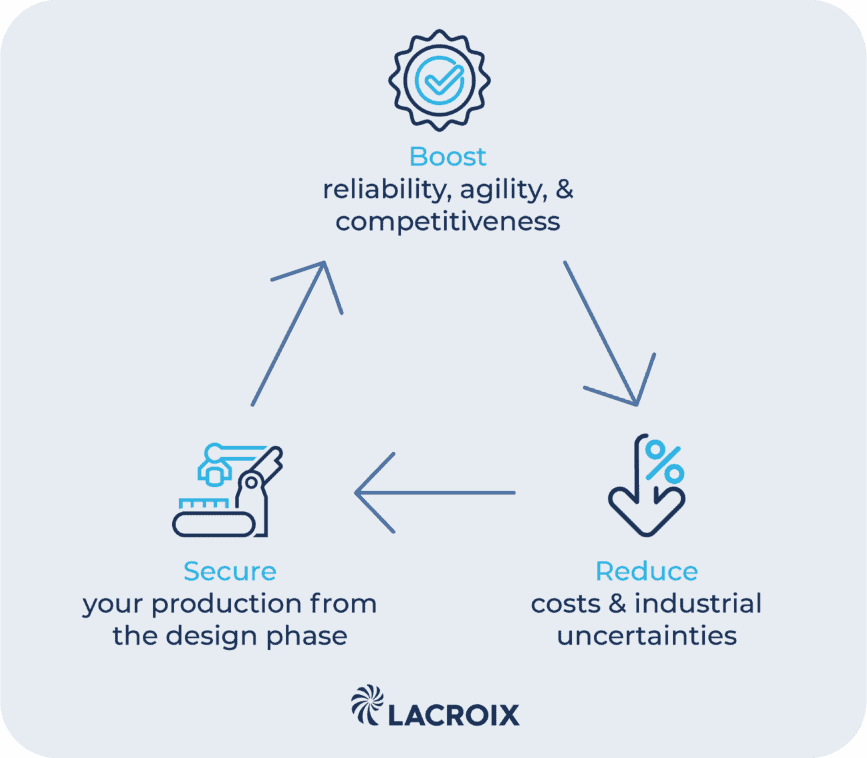

The combination of DfX + rapid prototyping + pre-series creates a continuous improvement loop where each step feeds the next, enabling faster innovation and a secure ramp-up to mass production.

DfX : Designing for performance and industrial scalability

DfX (Design for eXcellence) covers a set of engineering disciplines that aim to design products that are easier to manufacture, test, source, and assemble, while reducing risks and costs.

DfM (Design for Manufacturing)

Designing with manufacturing processes in mind to minimize rework and improve yield.

Case study – LACROIX:

For an energy management device, replacing an SMD connector with a Pin-in-Paste solution eliminated solder cracks, reducing the failure rate from 1% to 0% after validation.

DfP (Design for Procurement)

Optimizing product architecture while considering component availability, cost, and obsolescence risks.

Case study – LACROIX:

On an automotive exhaust controller, collaboration between design and procurement teams reduced component costs by 39% (from €2.62 to €1.88 per unit).

DfT (Design for Testability)

Defining the test strategy from the start ensures quality and reduces defect-related costs.

Case study – LACROIX:

For a telemetry platform, combining ICT and boundary scan testing increased test coverage from 30% to 85%, significantly improving product robustness.

By applying DfX early, manufacturers can reduce redesigns, shorten industrialization time, and enhance product quality across all stages of development.

Applying DfX can cut manufacturing costs by up to 30% and significantly reduce assembly time.

(Sources: Boston Engineering, aPriori, 6Sigma.us)

Go further with DfX case studies from LACROIX

Get access to real-world examples of DfX-driven projects at LACROIX, complete with:

- Measurable cost reductions,

- Time-to-market gains,

- Practical insights into co-design and component sourcing.

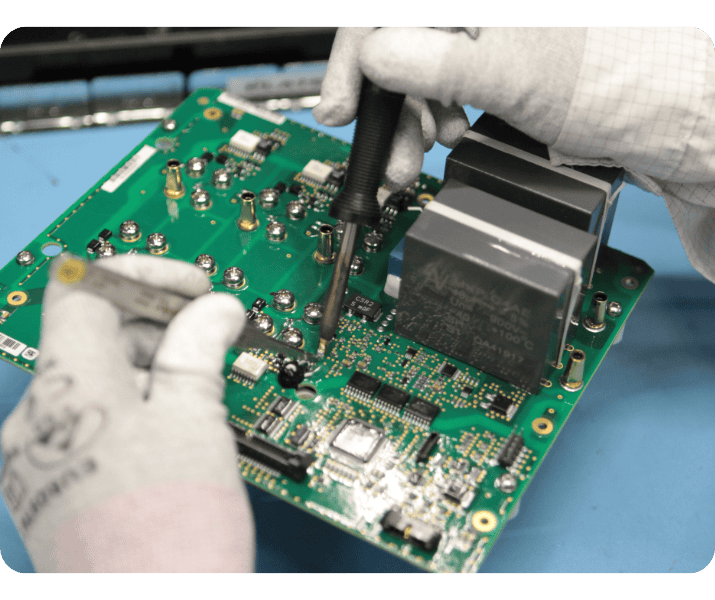

Fast prototyping: validating electronic designs faster

Rapid prototyping is a cornerstone of agile electronic product development.

Through accelerated component sourcing, and industrial-grade electronic assembly, engineers can validate design choices within days instead of weeks.

Projects leveraging this approach report up to 37% faster delivery and a 90% reduction in time-to-part compared to traditional methods.

(Sources: MoldStud, Stratasys)

LACROIX’s expertise in fast prototyping

With dedicated prototyping facilities in Beaupréau – France and Willich – Germany, LACROIX combines speed, agility, and industrial know-how to deliver:

- 75,000+ prototypes produced since 2005,

- 165 new product references developed every year,

- Expertise across automotive, avionics/defense, and industrial sectors.

Beyond the prototype itself, clients benefit from supply chain guidance, expert advice, and a dedicated point of contact ensuring project continuity.

Every prototype is tailored to project complexity and meets the highest industrial standards.

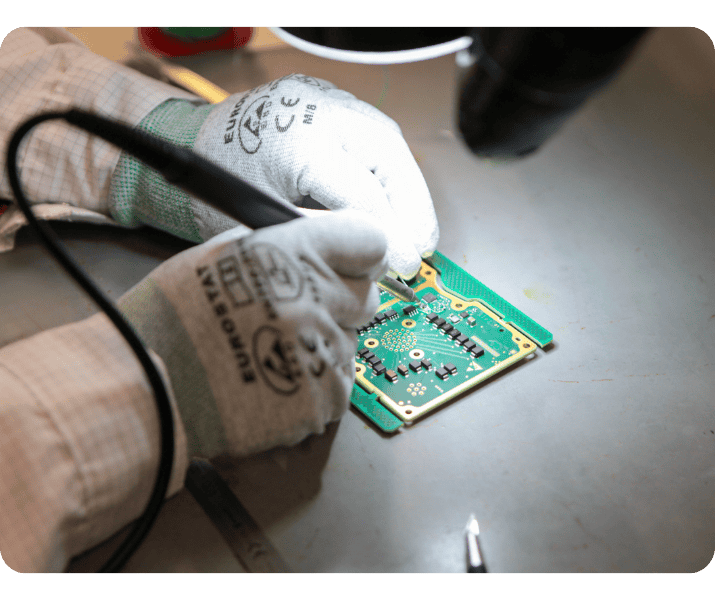

Pre-Series: securing the transition to mass production

The pre-series phase is often underestimated, yet it is critical for a smooth, risk-free industrial ramp-up.

It allows manufacturers to:

- Validate tooling,

- Fine-tune process parameters,

- Train operators,

- Detect potential issues early.

At LACROIX, pre-series production is carried out under final manufacturing conditions, ensuring that volume production starts predictably and efficiently.

This phase helps cut up to 70% of late stage engineering changes, preventing costly redesigns and launch delays.

LACROIX’s integrated approach: from prototype to series production

What truly sets Electronics apart is its coherent, end-to-end industrial model.

DfX, fast prototyping, and pre-series are not separate services, they form the three pillars of a unified industrialization process.

This integrated approach provides:

- Full visibility across the product lifecycle,

- Up to 30% faster time-to-market,

- A seamless transition from prototype to mass production,

…supported by multidisciplinary teams in R&D, methods, quality, and procurement.

The trio DfX – rapid prototyping – pre-series is now a strategic advantage for electronics manufacturers:

- Accelerate design and validation,

- Reduce costs and industrial risks,

- Enhance collaboration between design and production.

Ready to accelerate your electronic industrialization?

Contact our experts to discuss how DfX, rapid prototyping, and pre-series can help you bring your next product to market faster and smarter.